Sign in

Sign up

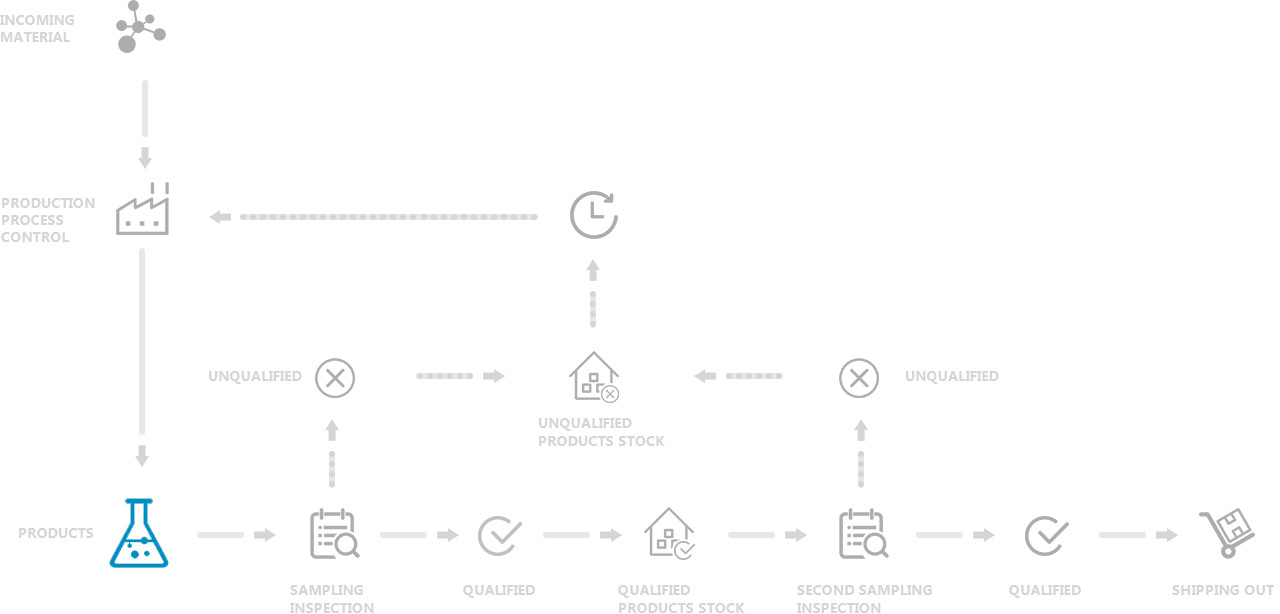

Quality Control

Quality is always of paramount importance, we do all we can do to meet the highest standards.

Most of the customers' main concern is quality. We can only win the trust of our customers with consistent quality.

Therefore, quality is the priority for RUIJIANG and we are determined to become the first brand of China in consistent quality. In order to acheive this, we work based on the following strict process:

For example of silicone oil:

-

We have strict raw materials testing for silicone oils before production, to make sure that that every batch of the raw materials meet our standards and no impurity such as Methyltriphenyl Siloxane included, so no cyrstallization problem will happen in our silicone oils.

-

After the production, we will take samples from every batch of the products to our lab for basic testing, such as viscosity, flash point, refractive index testing and then put the samples in (our testing devices) to have a performance testing to make sure that the performance of the products is qualified.

-

We will take the samples to our lab built together with Zhejiang University to have GC-MS testing to make sure that the purity of our products is ok, when we got the testing report, we will send the testing report to our customers for their checking, only they think the report is ok, then we will arrange the delivery, if it is not ok, we will destroy them and have another production until they are qualified.

-

Before the delivery, we will take a sample from the product under this batch and seal the sample, if our customers find any problem in our products some day, we can analyse the sample and compare it with the sample our customer send us to find out the reason. The samples sealed will be kept for 2 years.

Strict quality control system for water repellents:

Our strict quality control system ensures that the quality of our silicone products are the most consistent in China.

-

We have strict raw materials testing process for silicone water repllent before production, to make sure that every batch of the raw materials meet our standards and have no impurity included, so the quality of our products will be consistent.

-

After the production, we will take samples from every batch of the products to our lab for basic testing, such as solid content, PH testing, etc.

-

We will do some application testing in same building materials such as concret, sement mortar, brick, gypsum board, marble, etc to make sure that the water repellency our products are ok before the delivery.

-

Before the delivery, we will take a sample from the product under this batch and seal the sample, if our customers find any problem in our products some day, we can analyse the sample and compare it with the sample our customer send us to find out the reason. The samples sealed will be kept for 6 months.

R & D

RUISIL has a group of engineers and technician who have many year's experience in the silicone fields, we collaborate with Zhejiang University and Hangzhou Normal University and other developing center, devoting in promoting product application innovation & product quality improvement.